Light Class C250 Square Gutter Drain Cover

Square Gutter Drain Cover Advantage:

1. Stable process;

2. The best product features;

3. Advanced machining and inspecting equipment.

Square Gutter Drain Cover information

The entire great control management has been achieved throughout the whole manner of manufacture with the assistance of business enterprise and other manage device, which incorporates the uncooked material, production method manipulate, final product nice manipulate.

Software program: public carrier, advent, sewage disposal gadget, municipal engineering

Form: round, square, rectangle and triangle

Coating: water-based totally epoxy high paint

Processing: sand casting

Delivery detail: interior 7-30 days once we obtained the down price

Material: qt500-7

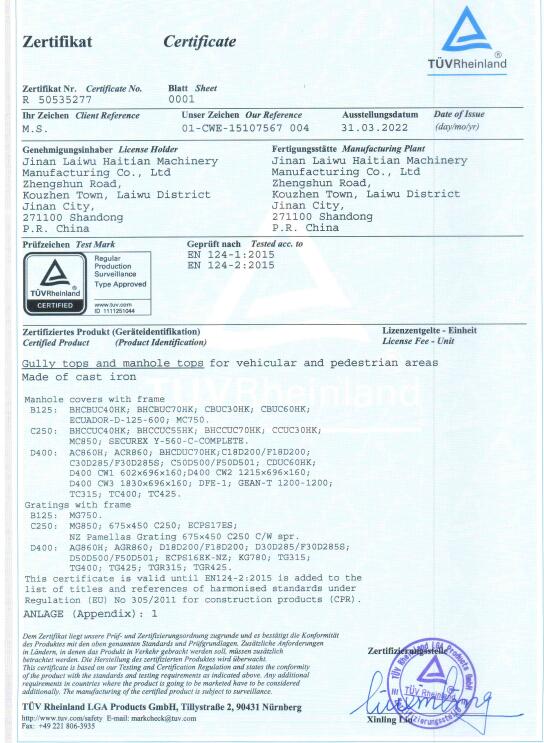

Certificates: bs en124:2015, iso9001:2008, iso14001:2015, iso45001:2018

Tensile power:≥500mpa

Yield power: ≥320mpa

Elongation price: ≥7%

Hardness: hbs170-230

Material: ductile solid iron

Floor treatment: non slip floor

Layout feature: anti-theft

Loading grade: a15, b125,c250, d400, e600,f900

Square Gutter Drain Cover Packing: Iron pallet, or as per customers' requirement

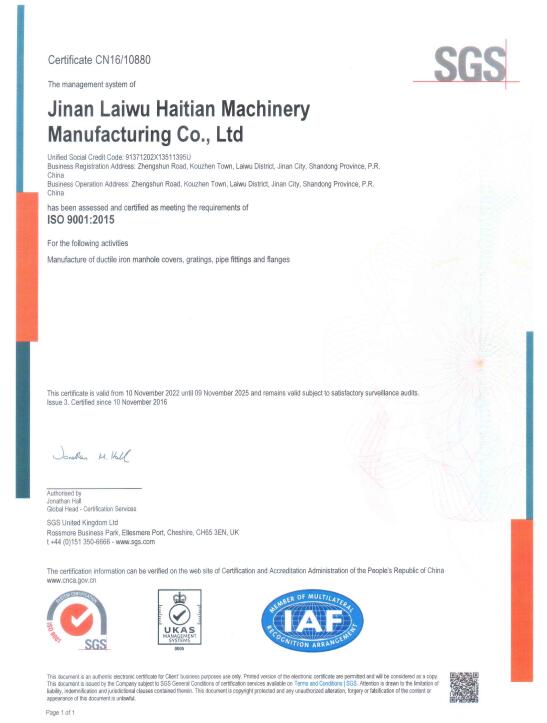

IS09001:2015 issued by SGS BS EN124-1 and BS EN124-2 Certificate issued by T

Square Gutter Drain Cover Delivery by container

FAQ:

1. What is the qualify assurance we provided?

We have a testing laboratory to check products at all stages of the manufacturing process-raw materials, process materials, validated or tested materials finished goods. Beside, we have Pressure Test Machine to test the load and permanent deformation. So we successfully get the ISO9001:2015 issued by SGS.

2. How do we control quality?

100% inspection in assembly lines. All controls, inspections, equipments, test machines, total production resources and skills are inspected to ensure they consistently achieve the required quality levels.

3. Why do you choose us to cooperate?

1.Our company is the factory, the best direct price.

2.Customized products according to clients’ drawing.

3.Our factory has 21 years history and rich manufacturing experience.

4.Professional Foundry Engineering Technology.